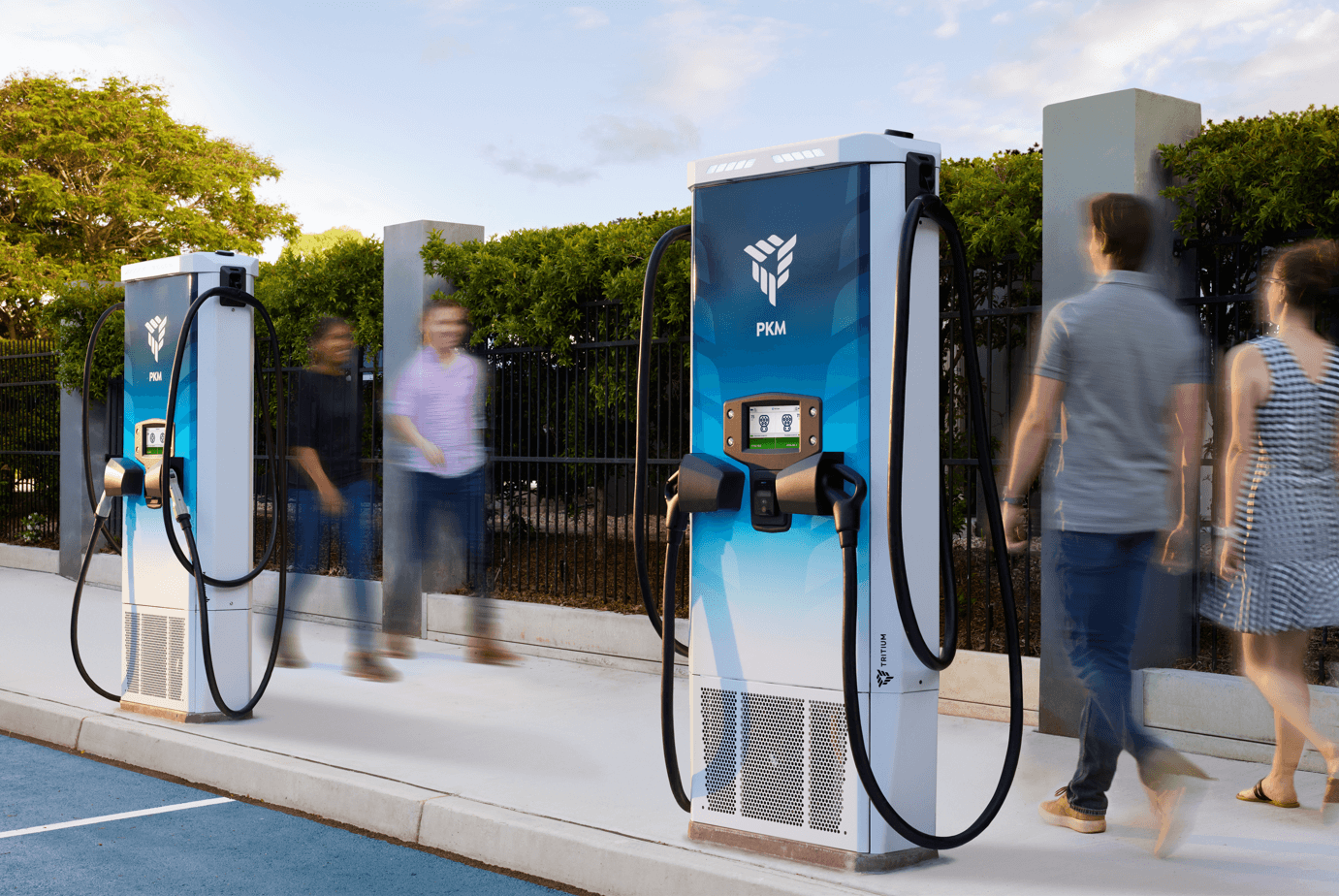

Maximum Efficiency, Uptime, and Throughput

Tritium chargers let you charge more vehicles more efficiently and reliably, meeting the growing demands of EV drivers and boosting your bottom line.

Charge Efficiently

Tritium’s advanced load balancing can take advantage of less-than-optimal site power feeds and distributes power in super-efficient 1kW increments. That means more of the power you pay for reaches customer cars.

Charge Reliably

The PKM150 is designed to withstand extreme conditions and can be easily maintained and repaired in the field thanks to its modular design and construction. Tritium customers report up to 98% uptime with their PKM150 chargers. The PKM150 is the charger drivers can rely on.

Charge More with Less

The Tritium NEVI system uses just two power rectifiers and light-gauge DC cabling. Both reduce overall costs significantly when compared to all-in-one charging systems without sacrificing performance, throughput, or reliability.

Charge More Vehicles

The Tritium NEVI system provides a total of eight charging ports compared to the competitor’s four*. That means you can charge more EVs at once, leading to shorter or no vehicle queues and more revenue.