Powering the Future: Tomorrow’s EV Batteries

The International Energy Agency expects worldwide EV sales to reach 14 million in 2023, and 28 million in 2024. They predict that by 2030 there will be 140 million electric cars on the road worldwide. Scientists, engineers, and manufacturers are developing new battery technology to meet demands—and to make EVs lighter, more efficient, more affordable, and be capable of faster charging.

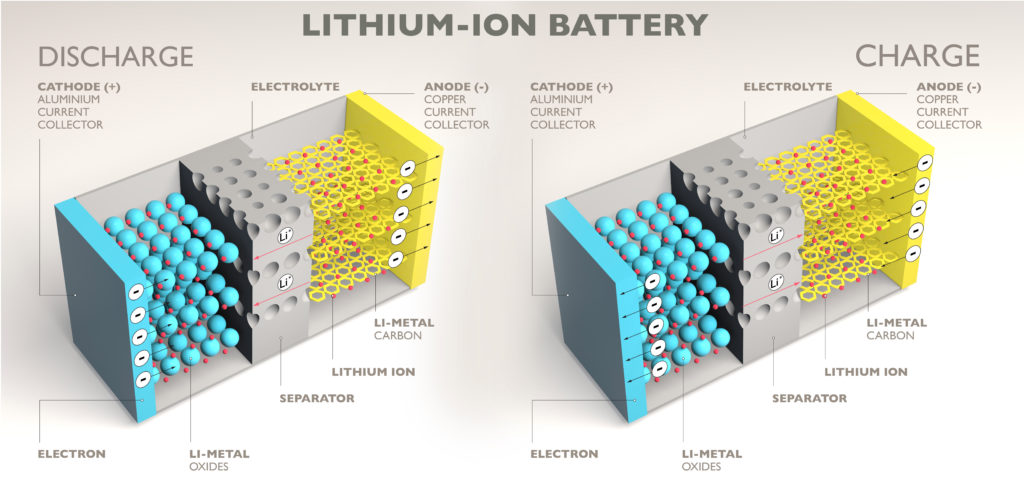

How Does a Lithium-Ion Battery Work?

Very simply put, lithium-ion batteries store and release energy via a chemical reaction. During this reaction, lithium ions move from one electrode to the other through a liquid electrolyte, either shedding or gaining electrons along the way. Run a current of electricity through the battery and it “charges.” Connect the terminals to a circuit and they discharge.

Solid-State Batteries

Commercial lithium-ion batteries contain a liquid or gel electrolyte. Solid-state lithium batteries use a solid electrolyte instead, reducing the overall size and weight of the batteries. Solid-state lithium batteries have several advantages over their liquid counterparts:

- Increased energy density: Solid-state batteries can store more energy in a smaller space.

- Faster charging: Current solid-state batteries can charge about twice as fast as liquid batteries.

- Enhanced safety: The absence of flammable liquid electrolytes reduces the risk of thermal runaway, making solid-state batteries safer.

Solid-state lithium batteries have been in development since the mid-1970s, but they haven’t been made commercially available in large quantities. Recently Toyota and Honda have announced plans to manufacture solid-state batteries, along with US battery manufacturer QuantumScape. Toyota claims they developed a breakthrough in manufacturing and hope to produce EVs with solid-state lithium batteries as soon as 2025. Honda hope their new solid-state battery tech will reduce the weight of their batteries by up to 50%. QuantumScape recently announced they’ll be producing a 5Ah solid-state lithium battery that could be used in EV battery packs. The company claims the battery can endure 800 charge cycles without significant degradation.

Nissan have also recently announced their solid-state lithium battery project, which they claim will go online sometime in 2028. And in 2022 GM announced they’re investing $7 billion in solid-state battery tech.

Toyota claim their solid-state battery could give EVs a range of up to 1,200km (745 miles) and charge in about 10 minutes. Other manufacturers are promising similar range and charge times, but haven’t provided real-world data as of yet.

Lithium-Sulfur Batteries

Most of today’s lithium-ion batteries use cobalt, an expensive and potentially dangerous element that’s only available in a few places on earth. Battery manufacturers are seeking alternatives to cobalt to avoid supply-chain interruptions and reduce costs. Many of the world’s largest cobalt mines in the Democratic Republic of Congo also have dangerous working conditions that endanger the lives of tens of thousands of miners. Reducing or eliminating the use of cobalt in lithium-ion batteries has many advantages. Lithium-sulfur batteries eliminate the need for cobalt or nickel, another rare element. They offer many benefits over lithium-cobalt batteries, including:

- Higher energy density: Lithium-sulfur batteries can potentially store more energy, offering greater driving range.

- Lower cost: Sulfur is abundant and less expensive than many other battery materials, potentially reducing production costs.

- Environmental benefits: Lithium-sulfur batteries use fewer toxic materials, making them more environmentally friendly.

However, lithium-sulfur batteries face challenges like shorter cycle life and issues with sulfur’s stability. Researchers are actively working to overcome these obstacles and bring lithium-sulfur batteries to the mainstream EV market. Researchers at the Argonne National Laboratory recently announced a major breakthrough in lithium-sulfur battery chemistry, uncovering a key chemical process that stabilizes the sulfur cathode. The researchers hope they can refine the process to produce longer-lasting, more energy dense lithium-sulfur batteries in the future.

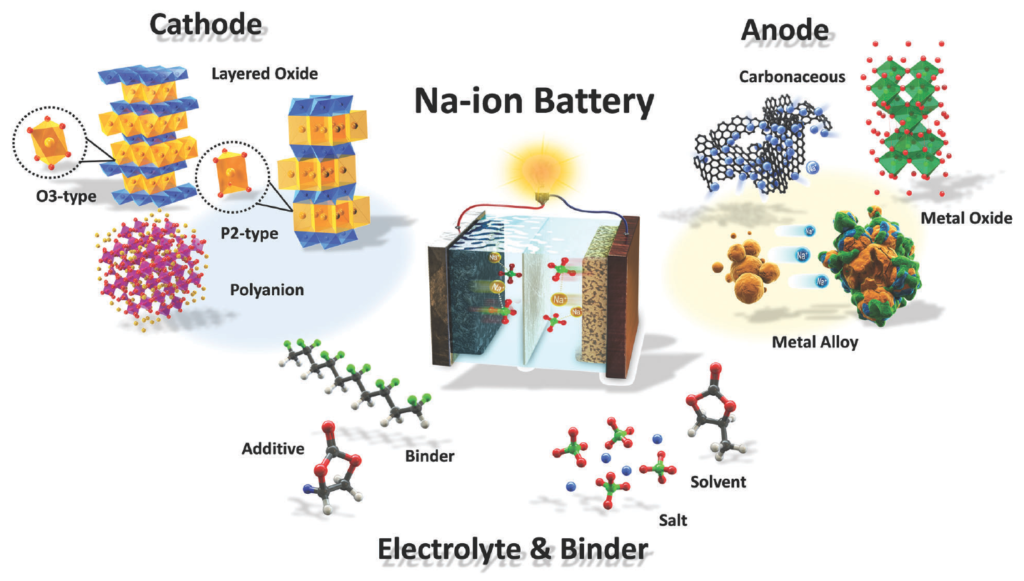

Sodium-Ion Batteries

Lithium-ion batteries of all forms have been popular for decades due to their power density and power output. But alternative battery chemistries are gaining popularity as lithium ore becomes harder to mine and lithium supply lines are stressed by increasing demand. Sodium lies just below lithium on the periodic table and has similar properties, but it is far more common and easier to process. Sodium-ion batteries promise to deliver most of what lithium batteries deliver, but at a much lower cost.

Sodium-ion batteries have been in development for more than 50 years, but they haven’t been commercially developed until recently. In the past, sodium-ion batteries weren’t able to match the energy density of lithium-ion batteries, were heavier, and deteriorated more quickly. Now some sodium-ion batteries are approaching the energy density of lithium-ion batteries and Chinese manufacturers CATL and BYD plan to release cars with sodium-ion batteries late in 2023. CATL plans to start mass-producing sodium-ion batteries in late 2023.

Sodium-ion batteries probably won’t replace lithium-ion batteries anytime soon, but they could be used in lower-cost EVs and for grid storage in the future.

Better Batteries, Faster Charging

Many next-generation batteries promise faster charging times than current batteries. Improving battery technology is crucial to improving charging times, making EVs more convenient for drivers everywhere. The world is rapidly building fast-charging infrastructure to ensure drivers can use their EVs for anything from daily commutes to road trips. The same fast-charging infrastructure will be crucial for electric commercial vehicles moving goods between cities.

At Tritium we work with EV manufacturers to ensure our chargers work flawlessly with the latest battery technology, conducting interoperability testing of vehicles at our facilities throughout the world. To learn more about our scalable, modular fast chargers, review our PKM150 fast chargers.

If you’re building the world’s fast-charging infrastructure, or if you’re interested in working with us to test your latest EVs before launching to the market, contact one of our experts today.