The International Energy Agency expects worldwide EV sales to reach 14 million in 2023, and 28 million in 2024. They predict that by 2030 there will be 140 million electric cars on the road worldwide. Scientists, engineers, and manufacturers are developing new battery technology to meet demands—and to make EVs lighter, more efficient, more affordable, and be capable of faster charging.

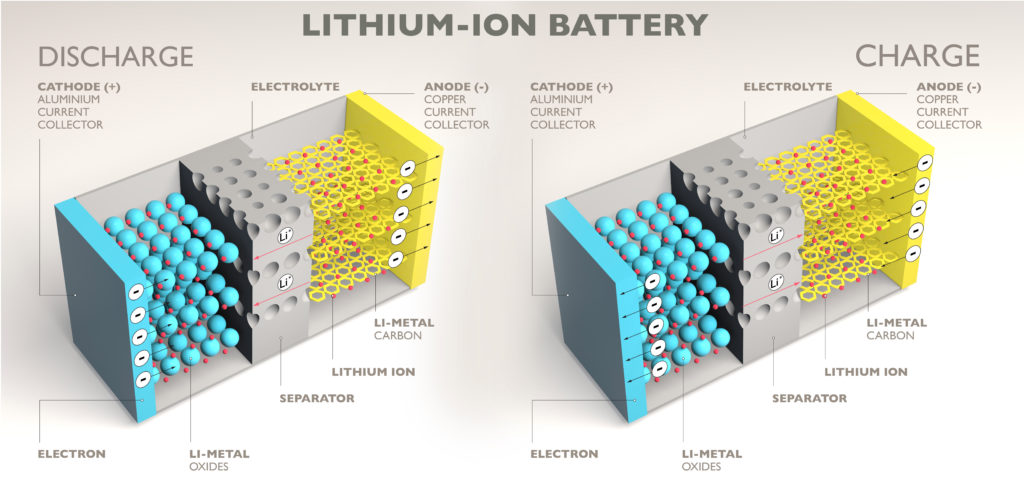

Very simply put, lithium-ion batteries store and release energy via a chemical reaction. During this reaction, lithium ions move from one electrode to the other through a liquid electrolyte, either shedding or gaining electrons along the way. Run a current of electricity through the battery and it “charges.” Connect the terminals to a circuit and they discharge.

Commercial lithium-ion batteries contain a liquid or gel electrolyte. Solid-state lithium batteries use a solid electrolyte instead, reducing the overall size and weight of the batteries. Solid-state lithium batteries have several advantages over their liquid counterparts:

Solid-state lithium batteries have been in development since the mid-1970s, but they haven’t been made commercially available in large quantities. Recently Toyota and Honda have announced plans to manufacture solid-state batteries, along with US battery manufacturer QuantumScape. Toyota claims they developed a breakthrough in manufacturing and hope to produce EVs with solid-state lithium batteries as soon as 2025. Honda hope their new solid-state battery tech will reduce the weight of their batteries by up to 50%. QuantumScape recently announced they’ll be producing a 5Ah solid-state lithium battery that could be used in EV battery packs. The company claims the battery can endure 800 charge cycles without significant degradation.

Nissan have also recently announced their solid-state lithium battery project, which they claim will go online sometime in 2028. And in 2022 GM announced they’re investing $7 billion in solid-state battery tech.

Toyota claim their solid-state battery could give EVs a range of up to 1,200km (745 miles) and charge in about 10 minutes. Other manufacturers are promising similar range and charge times, but haven’t provided real-world data as of yet.

Most of today’s lithium-ion batteries use cobalt, an expensive and potentially dangerous element that’s only available in a few places on earth. Battery manufacturers are seeking alternatives to cobalt to avoid supply-chain interruptions and reduce costs. Many of the world’s largest cobalt mines in the Democratic Republic of Congo also have dangerous working conditions that endanger the lives of tens of thousands of miners. Reducing or eliminating the use of cobalt in lithium-ion batteries has many advantages. Lithium-sulfur batteries eliminate the need for cobalt or nickel, another rare element. They offer many benefits over lithium-cobalt batteries, including:

However, lithium-sulfur batteries face challenges like shorter cycle life and issues with sulfur’s stability. Researchers are actively working to overcome these obstacles and bring lithium-sulfur batteries to the mainstream EV market. Researchers at the Argonne National Laboratory recently announced a major breakthrough in lithium-sulfur battery chemistry, uncovering a key chemical process that stabilizes the sulfur cathode. The researchers hope they can refine the process to produce longer-lasting, more energy dense lithium-sulfur batteries in the future.

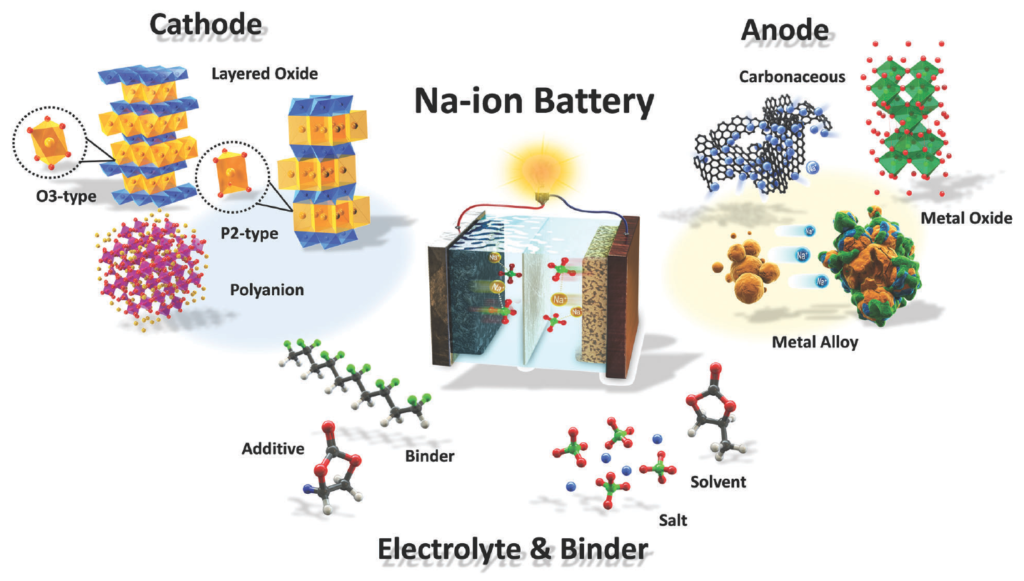

Lithium-ion batteries of all forms have been popular for decades due to their power density and power output. But alternative battery chemistries are gaining popularity as lithium ore becomes harder to mine and lithium supply lines are stressed by increasing demand. Sodium lies just below lithium on the periodic table and has similar properties, but it is far more common and easier to process. Sodium-ion batteries promise to deliver most of what lithium batteries deliver, but at a much lower cost.

Sodium-ion batteries have been in development for more than 50 years, but they haven’t been commercially developed until recently. In the past, sodium-ion batteries weren’t able to match the energy density of lithium-ion batteries, were heavier, and deteriorated more quickly. Now some sodium-ion batteries are approaching the energy density of lithium-ion batteries and Chinese manufacturers CATL and BYD plan to release cars with sodium-ion batteries late in 2023. CATL plans to start mass-producing sodium-ion batteries in late 2023.

Sodium-ion batteries probably won’t replace lithium-ion batteries anytime soon, but they could be used in lower-cost EVs and for grid storage in the future.

Many next-generation batteries promise faster charging times than current batteries. Improving battery technology is crucial to improving charging times, making EVs more convenient for drivers everywhere. The world is rapidly building fast-charging infrastructure to ensure drivers can use their EVs for anything from daily commutes to road trips. The same fast-charging infrastructure will be crucial for electric commercial vehicles moving goods between cities.

At Tritium we work with EV manufacturers to ensure our chargers work flawlessly with the latest battery technology, conducting interoperability testing of vehicles at our facilities throughout the world. To learn more about our scalable, modular fast chargers, review our PKM150 fast chargers.

If you’re building the world’s fast-charging infrastructure, or if you’re interested in working with us to test your latest EVs before launching to the market, contact one of our experts today.

On September 13, 2023, the Biden-Harris administration announced a $100 million program to help US states and government agencies repair and upgrade level 2 alternating current (AC) chargers and direct current (DC) fast chargers. Here’s what the program is all about and how you can apply for federal funding.

The EVCRAA is part of the National Electric Vehicle Infrastructure (NEVI) program, a $5 billion infrastructure program in the US to build a coast-to-coast EV charging network. The EVCRAA is a $100 million program that focuses on repairing or replacing broken or non-operational EV chargers to improve the reliability of existing EV charging infrastructure.

According to the US Department of Transportation, approximately 5,700 level 2 AC charging ports and 550 DC fast charging ports were listed as “temporarily unavailable” in the US as of September 11, 2023.

“We know that people expect public EV chargers to work the first time, every time,” said Joint Office of Energy and Transportation Executive Director Gabe Klein. “That’s why we have a multi-pronged approach to create a seamless charging experience by building a capable workforce, tracking reliability metrics, and convening industry to ensure they can meet the performance standards for federally funded chargers set earlier this year.”

State departments of transportation and local governments are eligible to apply for EVCRAA funding. States and localities can then work with manufacturers like Tritium, and maintenance providers to repair or replace non-operational chargers. Based on initial estimates of eligible chargers and the funding available, the US Department of Transportation anticipates that all eligible projects will likely be awarded under this program.

Projects must support repair or replacement of existing broken or non-operational publicly accessible level 2 AC chargers or DC fast chargers, as of October 11, 2023. States may apply for funding to repair or replace chargers identified as temporarily unavailable in the US as of September 11, 2023 by the US Department of Transportation. A full list of inoperable chargers by state can be found here. Chargers can be repaired, or replaced with upgraded equipment and must be operational within 12 months.

Chargers need to be NEVI and Buy America compliant; Tritium has chargers available now that meet these requirements with the short lead times necessary to meet operational conditions within 12 months.

States and government agencies may consider replacing broken level 2 AC chargers along designated Alternative Fuel Corridors with DC fast chargers using EVCRAA funds. Applicants are encouraged to include multiple locations to streamline the application process and review.

The federal government will cover up to 80 percent of the total cost of the repair/replacement project. Awardees must provide at least 20 percent of the total cost of the project as a matching share in cash or in-kind services.

States and government entities can apply for EVCRAA funds through the US grants website here. The deadline for applications is November 13, 2023.

The Tritium RTM75 (50-75kW) standalone DC fast charger is a compact, all-in-one charger for tight spaces like parking structures, retail environments, distribution centers, or warehouses. It’s designed to be easily maintained in the field thanks to its modular design and construction.

The Tritium PKM150 (100-150kW) distributed DC fast charging system is designed for highway rest stops, fuel centers, convenience centers, commercial depots and distribution centers, or anywhere passenger or commercial EVs need fast charging. The PKM150 makes the most of available grid power, dynamically distributing electricity to EVs based on their needs. That means greater efficiency, so you can charge more vehicles with less equipment and less-than-optimal power feeds. One PKM system with four chargers can charge eight EVs. The PKM150 is also designed to be easily maintained and repaired in the field thanks to its modular design and construction. Tritium customers report impressive uptime with their PKM150 chargers.

Tritium’s PKM150 NEVI system and RTM75 charger meet requirements of the National Electric Vehicle Infrastructure (NEVI) program and is assembled in our Tennessee facility.

To learn more about Tritium’s NEVI charging system, contact an expert today.

Load balancing is more than just an efficient way to distribute power to charging EVs. It can enable charge point operators (CPOs) to use less-than-optimal power feeds by maximizing available power capacity, save on electricity costs, and help them charge more vehicles overall. Here’s how.

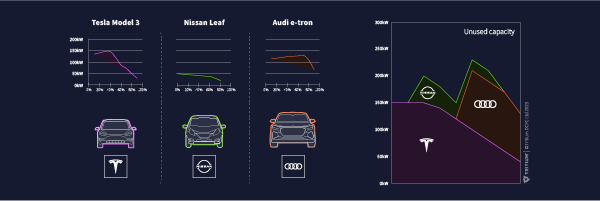

Tritium chargers use advanced load balancing algorithms to dynamically and efficiently distribute power among EVs in a charging hub. Load balancing provides the right amount of power to EVs at the right time. EVs don’t all charge at the same rate, and they don’t charge at the same rate over time from 0% to 100% battery capacity. EVs typically draw maximum power early in charging when they have a low state of charge to preserve battery health. Load balancing algorithms provide only the power each EV needs, leaving the rest of the available grid power to charge other EVs in the hub. To learn more, read our article about load balancing here.

Load balancing lets CPOs take advantage of less-than-optimal power feeds. Grid power is limited at many proposed charging sites, requiring CPOs to work with local utilities to upgrade site power to meet the needs of DC fast chargers. Load balancing lets CPOs build fast charging sites where grid power may not meet the full demands of all the chargers at the site.

For example, four 150kW chargers can draw a maximum of 600kW, which would require 600kW of site grid power. But thanks to charging curves and load balancing, four 150kW DC fast chargers will almost never draw a full 600kW simultaneously. A CPO can effectively install four 150kW chargers at a site that has 400kW of available power. One or two EVs at the site can utilize 150kW power for ultrafast charging while the other cars with a higher state of charge can utilize less power later in their charging sessions. This is known as “site oversubscription,” because the site initially contains more chargers than the power grid can support.

That means load balancing allows CPOs to install charging stations at more locations regardless of available grid power on site. As EV charging demands increase, CPOs can upgrade site power to match them over time.

The Tritium PKM system has a unique direct current (DC) grid that distributes power from the power cabinet (AC to DC rectification) to the chargers. DC cabling is light gauge and is about 30% of the cost of comparable alternating current (AC) cabling. The PKM DC grid also has less energy loss due to resistance than a comparable AC grid system. Overall, the PKM system is more than 99% efficient in converting AC grid power to DC. That means more of the power you pay for is delivered to charging EVs with minimal power loss.

Tritium’s unique granular 1kW load balancing system provides more available power for charging other EVs in the hub. When an EV requests 70kW of power, Tritium’s load balancing system can allocate exactly 70kW. In contrast, some other load balancing systems allocate power in larger 25kW increments. In this case, when an EV requests 70kW, the load balancing system allocates 75kW, leaving 5kW of power capacity unused.

When compared to other systems, Tritium’s built-in load balancing system makes more efficient use of available grid power. Because it can more effectively allocate power in granular increments of 1kW to charging EVs, the Tritium load balancing system can charge multiple EVs in less time than comparable systems.

Efficient charging is profitable charging. Tritium’s built-in load balancing system enables CPOs to achieve profitability quickly by reducing capital costs, facilitating a diverse range of charging locations, increasing overall efficiency, and charging more EVs faster.

To learn more about how Tritium charging systems with advanced load balancing can help CPO’s reach profitability faster, contact one of our experts today.

Shell Recharge, Parkopedia, and Plug-in America recently surveyed thousands of drivers around the world and the results are in: They want more public chargers that are easier to use and easier to find.

According to Parkopedia survey results, two thirds of all EV drivers worldwide and 73% of American EV drivers have run out of charge at least once. The same survey found that 22% of EV drivers across the globe and 25% of US EV drivers have run out of charge more than once. It’s clear that EV drivers everywhere could use better charging infrastructure. And when asked, they admit it.

Plug-In America found that about 42% of EV drivers they surveyed were concerned about charging stations being too far apart. Charger availability is also a major barrier to EV adoption. From Parkopedia: 52% of those surveyed who wouldn’t consider an EV are worried about the number and availability of chargers away from home. The same survey found that 53% of drivers who are considering an EV are worried about finding chargers away from home.

Parkopedia also found that more that 33% of drivers around the world stress about being able to find a charger when away from home. Range anxiety levels were highest in drivers in the US and France. And more than one in five drivers find it challenging to locate EV charge points away from home “very frequently” or “all the time.” In the US, 14% of EV drivers struggle “all the time” to find chargers away from home.

The lack of charging infrastructure in the US and some parts of Europe seems to be hindering EV adoption. More chargers in convenient locations will help alleviate fears and encourage more people to purchase and drive EVs. Better charger locating apps and app integrations will also help drivers find those chargers and plan long-distance trips more effectively.

EV drivers want easier ways to pay for public charging. Shell Recharge found that 47% of EV drivers they surveyed are willing to pay more for a single method of payment for charge points. And 73% of drivers surveyed would prefer an EV with integrated EV charging and payment.

More data from Parkopedia reveals how EV drivers are currently using public charging networks (excluding Tesla’s network, which was considered as separate from other networks). Around 27% of drivers use a card at charging locations, 25% use contactless payment, and 25% use app/website payment options. There were some differences in preferred payment systems among countries. For instance, UK EV drivers like to use contactless payment when charging, while French drivers like to pay by credit/debit card. RFID cards are the least popular payment type. There were also differences between urban and rural EV drivers: Urban drivers preferred apps, advance payments, and Plug & Charge while rural drivers preferred paying with a credit/debit card.

Unfortunately, Plug-in America found that broken or unavailable chargers in public charging networks (excluding Tesla) are the leading concern for EV drivers. About 37% of respondents said broken or unavailable chargers were a major concern and 9% said they were a dealbreaker for using a network. Maintaining high charger uptimes is critical for charge point operators, and for changing public perception about EV charging.

Tritium modular chargers are designed for reliability and maximum uptime. If a single module requires maintenance, Tritium chargers can still operate at reduced power until that module can be replaced. Tritium power modules are compact and lightweight and can easily be replaced in the field by a technician. Both our PKM150 and RTM75 chargers use the same power modules, leading to greater parts availability and faster repairs.

Tritium also offers robust service level agreements (SLAs) and works with certified repair and maintenance companies to ensure chargers achieve maximum uptime. Through these agreements, we can offer 24-hour support to Tritium customers across the globe.

To learn more about our chargers and service level agreements, contact an expert today.

DC fast chargers handle tremendous amounts of power and are exposed to harsh conditions. It’s crucial that charge point operators have robust service level agreements and maintenance contracts to ensure chargers remain available for drivers.

When it comes to fast charging, location is everything. Nearly half (49%) of Shell Recharge survey respondents said that they choose where to shop and travel based on the availability of charge points. More than half (57%) said they would visit destinations more frequently if they had charge points. Shell has also found through other research that EV drivers are willing to spend an hour or more at supermarkets while charging, which could boost sales for retail establishments with charge points.

According to the Parkopedia survey, EV drivers chose charging sites based on distance to the destination, charger availability, and charging cost. Charging cost was less important than location and in the US, EV drivers will pay more for convenient charging locations. Nearly two thirds said they’d be willing to pay a premium of up to 10% when charging at a convenient location. Almost a quarter of American EV drivers surveyed (23%) said they’d pay more than a 10% premium to charge up at a convenient location.

In January and February 2023 Shell Recharged ran an online survey. They sampled a total of 24,771 battery electric vehicle (BEV) or plug-in hybrid vehicle (PHEV) drivers in the UK (4,698 respondents), Germany (8,368), France (2,303), Italy (1,364), the Netherlands (6,715), and Belgium (1,305).

From December 2022 through February 2023, Plug In America surveyed over 3,300 electric vehicle (EV) owners and nearly 600 individuals interested in purchasing an EV.1 This survey builds on data collected from surveys conducted in 2020 and 2021.

Independent online survey of 5454 drivers, including 2225 EV drivers. The survey asked screening questions to understand drivers’ personal and car ownership and questions covering drivers’ parking and charging habits.

Tritium’s CSO David Nicholl recently spoke with the organizers of the London EV show about the future of EV charging. This article was published on their website on 31 August 2023.

As the global automotive industry undergoes a profound transformation, the rise of electric vehicles has become a central focus. With the shift towards sustainability and cleaner transportation solutions, the development of fast-charging infrastructure has emerged as an enabler of this transition. To delve into the intricate landscape of EV charging and its role in shaping the industry, we had the privilege of having a Q&A Session with David Nicholl, Chief Sales Officer of Tritium, a leading name in fast-charging technology. Let’s delve into the world of electric vehicle charging with David Nicholl, shedding light on the technologies, strategies, and visions that are driving this transformative journey.

David Nicholl: The biggest trend has been a vast investment in DC fast charging across the globe. There are now around 5,000 rapid and ultra-rapid charging points in the UK alone (ZapMap) and the government is making a huge investment to build out charging infrastructure even more.

But we’ll need even more rapid and ultra-rapid chargers if we want to meet driver demands and emissions targets. New EV sales in the UK were up almost 20 percent this year (Society of Motor Manufacturers and Traders). Those drivers want to know that there will be a rapid charging station within easy reach no matter where they are. And the chargers at those stations need to be operational. The UK government recently passed a 99% uptime or reliability standard for rapid and ultra-rapid chargers. That will greatly improve charger availability, but it’s important that operators have robust service level agreements and preventative maintenance contracts in place with charger manufacturers. Preventative maintenance measures must be adhered to, and spare parts should be readily available to maintain uptime.

It’s also important that we have charging infrastructure that can work with a wide variety of utility power levels and different vehicles. Tritium uses dynamic load balancing to make the best use of grid power and to deliver optimal power to EVs that have varying charging speeds. Load balancing lets us distribute power among chargers, delivering the right amount of power at the right time without much waste, and ensuring power capacity is better utilised and assets provide a better return.

Mr Nicholl: Again, dynamic load balancing is a big advancement in DC charging for EVs. Very basically, it lets charge point operators charge more vehicles at the same time. It knows how much power each EV needs at a given time and only provides what’s needed. It dynamically distributes power to charge multiple EVs very efficiently in increments of just 1kW, saving power and making better use of the available power grid minimising unused capacity. The power grid is a huge issue here in the UK. In many places we simply don’t have robust power feeds that can support multiple rapid or ultra-rapid chargers. Distributed systems like our PKM let charge point operators install rapid chargers even where grid feeds are limited.

Today’s advanced ultra-rapid chargers like our PKM150 are also modular and scalable. That means the power can be upgraded over time, and additional charging stations can be added to meet the future demands of EV drivers. They’re also more reliable and easier to maintain. If a single module in a charger has an issue, the charger can still operate at a lower power output until the module can be investigated by a technician and if needed, replaced in minutes. Serviceability and modularity are key to building reliable charging infrastructure.

Chargers now also include easy payment options and drivers don’t have to download an app or sign up with a charge point operator to charge their cars.

Mr Nicholl: Fast charging can eliminate range anxiety if it’s widely available. If EV drivers know they’re never more than a few miles (or kilometres) from a rapid charger, range anxiety disappears. That’s why it’s crucial to build vast rapid charging networks across the world.

Availability of fast chargers is also critical to advancing EV adoption. Drivers want to know that they will be able to accessibly recharge an EV when arriving at a charging site without having to wait or think about it, much like the experience ICE vehicle drivers have. By increasing availability, and visibility, to fast chargers, drivers will gain the confidence that they can go whenever, wherever and never be stranded.

Amenities in and around charging stations will also help address range anxiety. If drivers know there’s a coffee shop or even a vending machine nearby, they’re more likely to stop at that station.

Lastly, and most importantly, chargers need to be reliable. Broken or unavailable chargers only erode the public’s confidence in EV charging and EVs.

Mr Nicholl: We conduct extensive interoperability testing with EV manufacturers across the globe to ensure that our chargers are compatible with their latest vehicles.

Now most charging infrastructure is largely compatible with most EVs on the market. Across Europe auto manufacturers are all adopting the CCS2 connector standard, while you’re seeing a split between CCS1 and Tesla’s NACS connectors in North America.

Rapid chargers like ours can use any connector. For example, most of our chargers in the UK and Europe have connectors for CCS and CHAdeMO—the Japanese standard. And in North America we’re planning on offering our chargers with CCS and NACS connectors and many Tritium chargers in the US also have CHAdeMO.

Easy payment processing will also help with charger-EV compatibility. In the early days many charge point operators had their own apps or cards, you had to be a member to use their systems. Now many charge point operators are using credit card readers so anyone can use their chargers. All of Tritium’s chargers have the option for contactless credit card readers so anyone can use them without being a member of a charging network.

Mr Nicholl: Chargers for heavy machinery see much more abuse than other chargers. They need to be robust and capable of handling that abuse. All our chargers are weather sealed to keep dust and dirt away from sensitive electronic components and undergo robust impact testing to ensure resiliency in the field. They’re also designed to be easily maintained and repaired. Heavy machinery operators should look for chargers that can take a beating and that can be rapidly repaired. They should also have service level agreements, or SLAs, to ensure their chargers can be repaired right away if they’re damaged. I think once heavy commercial operators know they can count on their chargers and their service providers they’ll make the switch. Electric machines are far less complex than their diesel counterparts and they should be much less expensive to operate and maintain. Electric machines make a lot of sense, the charging infrastructure just needs to be there.

Mr Nicholl: Commercial vehicles have much larger battery capacities than passenger vehicles. They need ultra-rapid chargers to charge up in a reasonable amount of time so they can spend more time on the road moving goods and getting work done. From a business perspective, fast charging means you can use your fleet more, and use it more efficiently.

High-power chargers need more power from the grid, which operators will have to consider. Commercial vehicle chargers will also need to be durable because they’ll see more use and abuse.

High-power commercial charging stations are necessary for commercial vehicles, there’s no way around it. They’re crucial to long-distance trucking and other commercial industries. I predict that many commercial vehicle operators will build their own charging infrastructure. We have many commercial vehicle operator customers who install chargers at their depots and offices for their commercial EVs. That lets them take control of their energy or “fuel” costs and achieve greater operational efficiency. They can even offset some of those costs with solar panels, wind turbines, on-site storage, or other forms of clean and renewable energies.

However, the number of chargers and charge locations an EV fleet needs really depends on the size of the fleet, utilisation rates of the fleet, and the dwell or idle times for the vehicles. In some cases, EV commercial fleets may not need ultra-rapid chargers if they can charge up overnight using level 2 AC chargers.

Mr Nicholl: People love to interact with vehicles and talk to experts. Shows like this can help answer their questions and can inspire them to move away from ICE vehicles.

And business owners need to see how EVs can fit into their organisations, what the advantages are. And there are a lot of advantages. EVs just aren’t cleaner and better for the environment—and let’s be honest mandated in a lot of countries—they’re also cheaper to own and operate. Shows like this can demonstrate the many advantages that EVs have over ICE vehicles and help businesses make the switch.

These shows are also a good way for manufacturers, charge point operators, and businesses to review the latest regulations around EVs and EV charging. The UK is rolling out new regulations and Europe has its own plan for rapid charging in the next five to 10 years. Businesses need to know these regulations so they can future-proof their EV charging investments.

In June 2023, Ford and GM announced they’d be switching from the Combined Charging System (CCS) to Tesla’s North American Charging Standard (NACS) connectors for their future EVs. Less than a month later Mercedes-Benz, Polestar, Rivian, and Volvo also announced they’d support the NACS standard for their US vehicles in the coming years. The switch to NACS from CCS seems to have complicated the electric vehicle (EV) charging landscape, but it’s a great opportunity for charger manufacturers and charge point operators (CPOs). With NACS, CPOs will be able to charge more than 1.3 million Tesla EVs on the road in the US.

NACS is Tesla’s previously proprietary direct current (DC) fast charging connector standard—formerly known simply as the “Tesla charging connector.” It has been used with Tesla cars since 2012 and the connector design became available to other manufacturers in 2022. It was designed for Tesla’s 400-volt battery architecture and is much smaller than other DC fast charging connectors. The NACS connector is used with Tesla superchargers, which currently charge at a rate of up to 250kW.

The Magic Dock is Tesla’s charger-side NACS to CCS1 adapter. About 10 percent of Tesla chargers in the US are equipped with Magic Dock, which lets users select a CCS1 adapter when charging. EV drivers need to use the Tesla app on their phones to charge their EVs with Tesla chargers, even when using the Magic Dock CCS1 adapter. Here’s a video of the Magic Dock in action.

The CCS (Combined Charging System) standard was created in 2011 as a collaboration between U.S. and German automakers. The standard is overseen by CharIn, a group of automakers and suppliers. CCS contains both alternating current (AC) and DC connectors. GM was the first auto manufacturer to use CCS on a production vehicle—the 2014 Chevy Spark. In America, the CCS connector is usually referred to as “CCS1.”

CCS2 was also created by CharIn, but is used primarily in Europe. It’s a larger size and shape than CCS1 to accommodate Europe’s three-phase AC power grid. Three-phase AC power grids carry more power than the single-phase grids common in the U.S., but they use three or four wires instead of two.

Both CCS1 and CCS2 are designed to work with ultrafast 800v battery architectures and charging speeds up to and beyond 350kW.

CHAdeMO is another charging standard, developed in 2010 by the CHAdeMo Association, a collaboration between the Tokyo Electric Power Company and five major Japanese automakers. The name is an abbreviation of “CHArge de MOve” (which the organization translates as “charge for moving”) and is derived from the Japanese phrase “o CHA deMO ikaga desuka,” which translates to “How about a cup of tea?” referring to the time it would take to charge a car. CHAdeMO is typically limited to 50kW, however some charging systems are capable of 125kW.

The Nissan Leaf is the most common CHAdeMO-equipped EV in the US. However, in 2020, Nissan announced it would move to CCS for its new Ariya crossover SUV and would discontinue the Leaf sometime around 2026. There are still tens of thousands of Leaf EVs on the road and many DC fast chargers will still retain CHAdeMO connectors.

Auto manufacturers choosing NACS will have a big impact on the EV charging industry in the short term. According to the US Department of Energy Alternative Fuels Data Center, there are approximately 1,800 Tesla charging sites in the US compared to around 5,200 CCS1 charging sites. But there are approximately 20,000 individual Tesla charging ports compared to about 10,000 CCS1 ports.

If charge point operators want to offer charging for new Ford and GM EVs, they’ll need to convert some of their CCS1 charger connectors to NACS. DC fast chargers like Tritium’s PKM150 will be able to accommodate NACS connectors in the near future.

Some US states, like Texas and Washington, have proposed requiring National Electric Vehicle Infrastructure (NEVI)-funded charging stations to include multiple NACS connectors. Our NEVI-compliant fast charging system can accommodate NACS connectors. It features four PKM150 chargers, capable of delivering 150kW to four EVs simultaneously. In the near future, it’ll be possible to equip each one of our PKM150 chargers with one CCS1 connector and one NACS connector.

To learn more about our chargers and how they can work with NACS connectors, contact one of our experts today.

If charge point operators want to offer charging for many future Ford, GM, Mercedes-Benz, Polestar, Rivian, Volvo, and possibly other EVs equipped with NACS connectors, they’ll need to update their existing chargers. Depending on charger configuration, adding a NACS connector could be as simple as replacing a cable and updating charger software. And if they add NACS, they’ll be able to charge approximately 1.3 million Tesla EVs on the road in the US. Tesla cars represent around 60% of all EVs currently in the US and the manufacturer is expected to maintain that share (or close to it) as the number of EVs increases.

NACS represents a huge opportunity for CPOs and charger owners. For minimal expense, CPOs can enter the expansive Tesla charging market—without asking EV drivers to carry or use their own NACS to CCS adapters.

By Matt Stace, Senior Sales Manager, Tritium

Tritium’s senior sales manager for Europe Matt Stace recently sat down with sustainable transport experts Electronomous to talk about EV charging in Europe. This article appeared in their annual publication “Global Thought Leaders’ Predictions for Mobility 2023.”

Norway, one of the earliest consumer markets to embrace electric vehicles, has steadily increased the number of full or partial electric passenger vehicles registered over the last decade. While Norway now leads the world with fully electric vehicles comprising 20.9% of the national vehicle fleet, the rate of growth over the last 10 years has allowed the orderly establishment of charging infrastructure such that the ratio of electric vehicles to chargers has actually fallen. Norway has largely avoided charging bottlenecks.

Multiple data sources confirm a much more rapid increase in the number of electric vehicles in other markets. EVs in Germany, for example, moved from 2% to 10% market share in just 12 months, less than half the time taken in Norway. Denmark recently surpassed 100,000 registered EVs in 2022, and more than 21% and 33% of new vehicles registered in Denmark and Sweden during 2022 were fully electric.

In cities where drivers have no access to at-home charging, it is highly likely that charging bottlenecks will appear if a corresponding increase in the number of public chargers does not occur. To meet the twin goals of maximizing the number of available plugs for drivers and ensuring an adequate return on investment for operators, it is important that operators invest in chargers that provide a power level that matches the time a driver expects to spend at the location.

Battery chemistry, state of charge, software and temperatures all determine how fast an EV charges, rather than the maximum power output of the charger. In a type of charger arms race, some operators are making the expensive mistake of installing chargers with ever increasing rates of power output regardless of the charger’s location. An average passenger vehicle during an average charging session absorbs power at a much lower rate than the peak output available from many such chargers. A recent study in Denmark found that a group of new electric cars charge at an average rate of just 62kW.

For all but a few operators, investing in high-power chargers in locations where drivers do not require it will come at the expense of providing more plugs to meet the needs of the growing car fleet. There is a strong financial case to be made that installing a larger number of mid-power charging stations sufficient to meet the real-world needs of a growing EV fleet is a far more capital efficient way to invest in charging infrastructure and to avoid the type of charging bottlenecks that drivers hate. If given the choice, most EV drivers would prefer to have access to some power — even at less than the peak rate their vehicle can accept for a short period — than wait in line for a high-power plug to be available.

Building charging infrastructure that thoughtfully matches potential power output to real-world needs rather than a single-minded focus on providing high-power chargers with capacity that may never or rarely be used, is one way to ensure that drivers do not experience bottlenecks as the fleet of passenger vehicles electrifies.

Want to learn how capital efficient EV charging systems can work for you? Contact Tritium today!

Sustainability is crucial to building a better world. During Earth Month we’re exploring ways businesses can improve sustainability through electric vehicles and electric vehicle charging.

Electrifying transportation is key to reducing greenhouse gas (GHG) emissions and mitigating the effects of global warming. According to the International Energy Agency (IEA), about 37% of CO2 emissions in 2021 came from the transportation sector. Transitioning to electric vehicles (EVs) can help reduce GHG emissions and avoid climate disaster.

But there are immediate benefits to electrifying your fleet: Switching your fleet to EVs can save you a lot of money in long-term fuel and maintenance costs, give you more control over when and where you fuel or charge up, and even help you operate in more locations across the globe.

EVs eliminate tailpipe emissions and greatly reduce GHG emissions even when they’re charged with power generated with fossil fuel powerplants. EVs are far more efficient than ICE vehicles, which means it takes less energy of any type (even fossil fuel energy) to move them. Higher efficiency means fewer GHG emissions. Additionally, it’s easier to control emissions at a few power plants than it is to control them in millions of vehicles. Lastly, EVs can also easily be powered by renewable energy sources like solar, wind, wave, and geothermal power.

Switching to EVs can also help offset your business’ carbon emissions, reducing tax burdens and helping to avoid any future penalties or fines for carbon emissions.

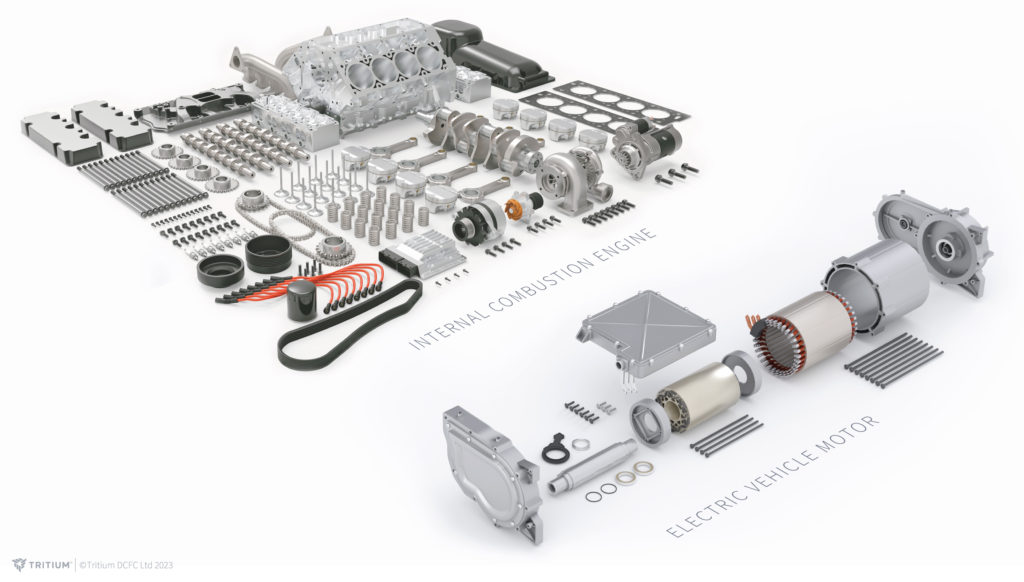

EVs are inherently less complex than ICE vehicles. According to a recent Forbes article, the typical internal combustion engine (ICE) drivetrain has about 2,000 moving parts while a typical EV’s drivetrain has about 20. And because EVs have fewer moving parts, it’s estimated their drivetrains (motors and transmissions) should last much longer than their ICE counterparts. Many EV drivetrains are engineered to run for up to 500,000 miles without service.

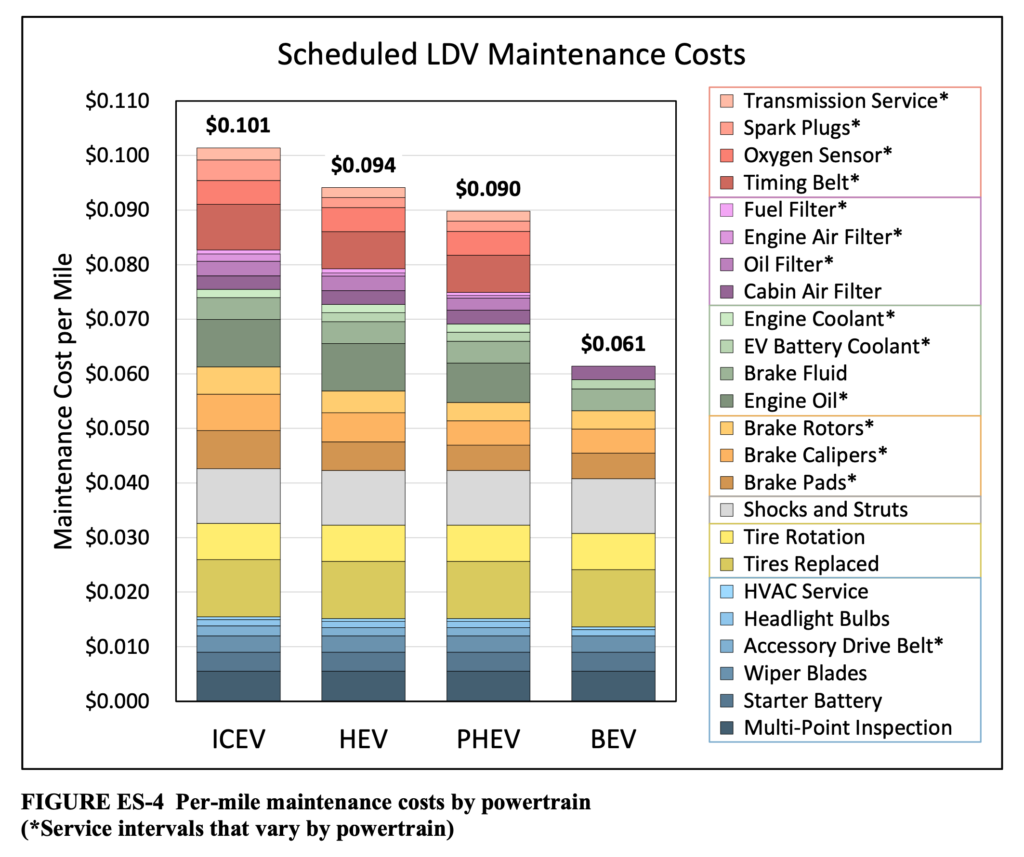

According to a study by the US Office of Energy Efficiency and Renewable Energy, the estimated scheduled maintenance costs for ICE vehicles is approximately 10.1 cents per mile compared to just 6.1 cents per mile for EVs.

According to Consumer Reports, EV drivers pay half as much for repairs and maintenance. Consumer Reports also found that EV drivers can expect to save an average of $4,600 in repairs and maintenance over the life of the vehicle.

More research by the Department of Energy’s Argonne National Laboratory found that EV maintenance costs are 30% lower than ICE vehicles.

Diesel and gasoline prices fluctuate wildly, but they have steadily rose over time and are subject to large price increases due to conflicts, natural disasters, and political turmoil. These events often have more of an effect on fossil fuel prices than electricity prices. And while electricity prices have risen significantly in Europe, they are still lower than the price of gas or diesel when used for transportation. A recent study by Dutch automotive lease provider Leaseplan found that despite energy price inflation, “fuel costs remain significantly lower for electric cars than petrol and diesel cars: fuel costs represent 15% of the total cost of ownership of an EV, while this is 23% and 28% for petrol and diesel drivers.”

EVs will almost always have lower fuel costs than ICE vehicles because they are more efficient. According to Motortrend Magazine, between 74 and 84 percent of the energy contained in gasoline is lost to heat and friction in an ICE vehicle. If you were to spend €1.80 on a liter of gasoline, only €.36 worth of it is used to move your vehicle. In comparison, only 31-35 percent of the energy in an EV’s batteries is wasted: 10 percent of the source energy from the grid lost in the charging process, 18 percent lost to the drivetrain motor components, up to 4 percent lost to auxiliary components, and another 3 percent lost through powertrain cooling and other vehicle systems.

ICE vehicles rely on networks of fuel stations that may or may not be near your established routes. If you build your own charging network, EVs give you the freedom to charge up when and where you want. Installing EV fast chargers at your offices or distribution centers can:

EVs can charge up overnight and run all day. Amazon plans to deploy a fleet of more than 100,000 EVs for last-mile, in-town deliveries by 2030. The retail giant will use Rivian delivery trucks and trucks from other manufacturers for deliveries across the world. Amazon expects the trucks to run for 12 hours a day and to charge up using DC fast chargers at Amazon distribution centers. The vans are expected to have a 300,000-mile lifespan before major maintenance, greatly reducing total cost of ownership. With these Rivian vans and DC fast charging at its distribution centers, Amazon can eliminate fuel stops and reduce downtime during operating hours.

Many governments around the world are offering financial incentives to make the switch to EVs. Nearly every country in Europe also offers some form of incentive to purchase EVs and EV charging equipment. The European Automobile Manufacturer’s Association (ACEA) has compiled a comprehensive list of EV incentives by European member countries. Many countries are offering thousands to offset the cost of new EVs, and most also offer incentives to purchase EV charging equipment. For example, France is offering up to 40% off the purchase and installation costs of EV charging points for businesses and public entities. There are also many other regional and city incentives available throughout Europe.

In the United Kingdom, the government offers up to £2,500 in incentives for the purchase of a new electric car. Additionally, the UK government has approved £30 million of funding in 2022 to 2023 for fast charging infrastructure, including DC fast chargers. The UK government is authorizing up to £13,000 in grant money per public charge point.

In the US, many states offer tax credits for electric delivery vehicles, and the $1.2 trillion Bipartisan Infrastructure Law includes $5 billion to help states build extensive EV charging infrastructure. There are also many state and regional incentives in the form of tax credits or grants available in the US. You can read more about them in our article here.

In Australia, the Treasury Laws Amendment (Electric Car Discount) Bill provides $2000 off the price of battery-electric and plug-in hybrid vehicles (PHEV). The bill also delivers Fringe Benefits Tax (FBT) exemptions for fleets and novated leases. Australia also raised the Luxury Car Tax threshold for low-emission vehicles to $84,916, from $71,849. The FBT savings amount to about $4700 for an individual.

Our experts can help you plan your fleet’s transition to electric vehicles. Our experts have decades of experience helping logistic companies, public transportation agencies, trucking companies, and rideshare companies integrate EVs and EV fast charging into their business models.

Electric vehicles (EVs) are great for deliveries, maintenance, and other commercial businesses within city limits. They are clean, quiet, and ultra-efficient at lower inner-city speeds. They could also be the only option for running your commercial business downtown as more metros across the globe restrict or ban internal combustion engine (ICE) vehicles in cities. Madrid has already banned ICE vehicles in its downtown and Paris, Athens, and Mexico City have all agreed to ban diesel-powered vehicles by 2025. If you are a building maintenance provider, tradesman, florist, window washer, cleaning company, mobile auto detailer, mobile auto maintenance provider, mobile dog groomer, or any type of small, medium, or large business, you will need EVs to serve customers in many major cities around the world.

Thankfully, many manufacturers are bringing electric vans and commercial vehicles to market, and many have already secured orders from world’s largest retailers and logistics companies and are selling their vehicles to businesses around the world. Here are some new commercial EVs hitting the market in the coming months that could help you make your business more sustainable and prepare you for future legislation or limiting of diesel-powered vehicles.

California-based Mullen Automotive is delivering its I-Go micro delivery vehicle to European cities in 2023. The compact four-door hatchback is perfect for last-mile deliveries in dense European cities. The I-Go is essentially a rebadged Chinese Xiaohu FEV car. It features a 16.5kWh battery pack that is good for 124 miles (200km) on a single charge thanks to the car’s small size and light weight. With a top speed of just 62mph (100kph), the I-Go will not be a great highway vehicle, but with a 34kW motor it will have enough power to compete with urban traffic.

The I-Go meets EU standards and will be available for sale throughout Europe, the UK, Australia, and the US. Mullen has priced the I-Go at just $11,999 (£9900).

French car maker Citroën has released the ë-Dispatch modular electric cargo van in Europe and the UK. The van can be configured for delivery, maintenance work, carpentry, or any other trade its owners need it for. Accessories include exterior cargo racks, interior shelving, and tow hitches. The van has a range of 196 miles (315km) with a 75kWh battery and can charge up to 100kW, giving it 80 percent charge in about 30 minutes. It can carry up to 1,400kg (3,086 pounds) and has about 6,600 liters (233 cubic feet) of cargo volume. The van has a built-in infotainment system, a spot to hold a tablet, and hands-free sliding doors. The ë-Dispatch has a starting price of about £26,000 in the UK.

California-based Canoo made headlines last year when it announced that retail giant Walmart agreed to purchase 4,500 of its new electric Lifestyle Delivery Vehicle (LDV) electric vans. Several pre-production LDVs were rolled out for testing in Dallas, Texas in 2022 and Canoo plans to deliver production LDVs to Walmart in 2023. Walmart can purchase up to 10,000 LDVs for last-mile deliveries across the US, but the LDV will be available to other businesses too. Canoo has not released official pricing for the LDV, but the company’s consumer Lifestyle Vehicle passenger van is priced at $39,950.

The LDV is equipped with comforts like a tilting, telescoping, heated steering wheel, heated seats and mirrors, automatic wipers, a 10.2-inch touchscreen, and nearfield communication (NFC) smartphone keyless interface. Canoo can also outfit the LDV with interior power outlets, shelves and racks, bin and tote management systems, and roof racks. Last, but not least, Canoo offers custom vinyl wraps for company branding. The Canoo promises to be a great option for small-to-medium businesses looking to electrify their commercial vehicles.

Retail juggernaut Amazon agreed to purchase 100,000 Rivian delivery EVs for use in the US and worldwide. The first 1,000 Rivian Electric Delivery Vans (EDVs) have already been making deliveries around the US. The EDV is offered in three lengths with three different cargo capacities—500, 700, and 900 cubic feet (25,485 liters max). The front-wheel-drive vans have a range of about 150 miles (240km) loaded and can charge at 50kW. It has a heated and air-conditioned driver’s seat and a full infotainment system onboard. The cargo area is outfitted with LED lighting and shelves to store packages. The EDV also uses modular body panels that can be easily replaced if damaged. Rivian has not released pricing for the EDV, but the company plans to start selling them to companies other than Amazon in 2023. The Rivian EDV is larger than the Canoo, but could be a great option for business who need to carry larger cargo or who need more interior space for equipment and power tools.

BrightDrop, General Motors’ electric van subsidiary, has sold 2,500 of its electric delivery vans to shipping giant FedEx. The shipping company could purchase up to 10,000 BrightDrop EVs in the future and Walmart has also placed an order. The BrightDrop Zevo 600 can haul up to 2,200 pounds (998kg) and has about 250 miles (402km) of range. The van was designed for utility with low step heights and a configurable area. Pricing info for the Zevo 600 has not been released yet. A smaller Zevo 400 for tight urban environments is also in the works. BrightDrop EVs may be available in Europe in the future, but for now they are only available in the US.

The venerable Ford Transit has gone electric. The E-Transit van is available in three different roof heights, three body lengths, and three configurations. The vans have a range between 108 miles (173km) and 126 miles (202km) and can be equipped with Ford’s 2.4kW Pro Power Onboard power supply that can be used for power tools. It also comes standard with Ford’s SYNC infotainment system and air conditioning. The flexibly utility van starts at $49,575 and can be equipped with a wide variety of gear to make hauling and working easier. It is also available in a variety of colors. The Ford E-Transit is available in the US, Europe, and the UK.

Spartan Motors (now known as the Shyft Group) has built more than half of all Class 3 through 5 square-bodied, riveted walk-in vans on the road in the US. The Michigan-based company oversees truck and truck chassis manufacturers Spartan RV, Utilimaster, Strobes-R-Us, General Truck Body, Royal Truck Body, DuraMag and Magnum, and Blue Arc. Blue Arc is the company’s foray into electric delivery vehicles and their first EV is a modular, configurable Class 3 to 6 delivery van (12-16-foot length options). The van uses a new motor/differential from well-known driveline manufacturer Dana. In traditional rear wheel drive drivelines, power is sent from the engine or motor do the rear wheels via a driveshaft. Dana has mounted the motor directly on the rear differential, negating the need for a driveshaft.

The Blue Arc can be outfitted with two 164-240kWh battery packs good for about 150 miles of range when loaded to 50-percent capacity. The Blue Arch motor and battery runs on 800-volt architecture, meaning it can charge up its batteries in just two hours. For now, Blue Arc electric vans are only available in the US, but they could be a great option for businesses that need extra cargo and hauling capacity for large-scale jobs.

If you want to learn more about how to electrify your fleet, contact one of our experts today.